LINCOLN ELECTRIC SVM123-A IDEALARC DC 1000

- Idealarc 100

- Idealarc Dc-1000 Service Manual

- Lincoln Idealarc Dc 1000 Manual

- Idealarc Dc 1000 Service Manual Instructions

- IDEALARC DC-1000 OPERATOR'S MANUAL For use with machines Code 9919 - 9925 & 10293 IM420-A July, 1999 Safety Depends on You Lincoln arc welding equipment is designed and built with safety in mind. However, your overall safety can be increased by proper instal-lation. And thoughtful operation on your part.DO NOT INSTALL, OPERATE OR REPAIR THIS.

- For use with machines having Code Numbers: 9919 thru 11684, 12480, 12736, 12737, 12738, 12739.

- . Semiautomatic DC Constant Voltage (Wire) Welder. DC Manual (Stick) Welder. AC Welder with Reduced Voltage Control. In semiautomatic or automatic wire welding, the electrode, electrode reel, welding head, nozzle or semiautomatic welding gun are also electrically 'hot'. Always be sure the work cable makes a good electrical.

- Lincoln Electric IM420 IDEALARC DC-1000 Manuel d'utilisation. Merci, Avertissement, Attention. Equipement Lincoln Electric.

113

Good luck to the repair!

Please do not offer the downloaded file for sell only use it for personal usage!

Looking for other manual?

Lincoln Electric Idealarc DC-1000 Operators Manual - Page 1. Document Details: 52 pages, 2.23 MB filesize. To talk to a Service Representative.

- If you have any question about repairing write your question to the Message board. For this no need registration.

- Please take a look at the below related repair forum topics. May be help you to repair.

If you are not familiar with electronics, do not attempt to repair!

You could suffer a fatal electrical shock! Instead, contact your nearest service center!

so you need WinZip or WinRar to open that files. Also some files are djvu so you need djvu viewer to open them.

These free programs can be found on this page: needed progs

If you use opera you have to disable opera turbo function to download file!

If you cannot download this file, try it with CHROME or FIREFOX browser.

I am looking for a schematic for a everlast power tig 210 ext before 2015

Seems to be a Chinese welding Maschine with 200 amps ac dc and microcontroller..

Which was also sold in Germany as Evo 200 ac/dc (my model)

Seems to be that the problem is on a board called acdc2100cp which Controls the main switching powersupply.

Problem is: no output.. 24v on the out. But delivered by a second powersupply.

Also hf is working.. But no startup arc. Primary voltage about 300V..

So without a schematic.. I am a little screwed.

I like the Maschine it's build well... Better than the analog tig welders

Regards Nils

or write your question to the Message board without registration.

You can write in English language into the forum (not only in Hungarian)!

MULTI-PROCESS WELDERS

Idealarc® DC-600

Rugged Multi-Process Power for Industrial Manufacturing

If your operations include semiautomatic manufacturing or fabrication, your best welding power source selection may be the Lincoln Idealarc® DC-600. Rugged construction, simple controls and plenty of amperage for heavy duty applications on thick steel or other materials make this welder a sound investment. Add the outstanding traditional SCR rectifier arc action delivering high quality, attractive welds and your operators will agree – it's hard to go wrong with an Idealarc® DC-600.

Processes

Stick TIG MIG Flux-Cored Submerged Arc Gouging

Advantage Lincoln

•115V, 15 amps, duplex auxiliary power receptacle (60Hz models) makes it easy to power lights, grinders and other shop tools at your work station.

•Full range output voltage control for easy operation and precise control.

•Standard analog ammeter and voltmeter.

•Mode switch for selecting desired output characteristics.

•Windings and rectifiers protected against moisture and corrosive environments.

•Flat-top case with a small footprint can be placed under a workbench or stacked up to 3 high on top of each other.

•Manufactured under a quality system certified to ISO 9001 requirements and ISO 14001 environmental standards.

•Three-year warranty on parts and labor.

•Seven-year warranty on the power rectifier.

Description

Output | CC | DC | Input 3 | 60 |

CV | PHASE |

Sham pistols. Recommended General Options

Multi-Process Switch, Undercarriage, Paralleling Kit

Recommended Stick Options

Accessory Kit, Remote Output Control, Remote Control Cable Adapter

Idealarc 100

Recommended TIG Options

Pro-Torch™ TIG Torches, TIG Module, Control Cable, Control Cable Extension, Docking Kit, Hand Amptrol, Foot Amptrol, Amptrol Adapter Kit, Water Valve Kit, Deluxe Adjustable Gas Regulator and Hose Kit

Recommended Wire Feeder Options

LF-72, LF-74, LN-742, LN-8, LN-9, LN-9 GMA, LN-10, DH-10, LN-15, LN-23P, LN-25, LN-35, Cobramatic®, NA-3, NA-5, LT-7

or write your question to the Message board without registration.

You can write in English language into the forum (not only in Hungarian)!

MULTI-PROCESS WELDERS

Idealarc® DC-600

Rugged Multi-Process Power for Industrial Manufacturing

If your operations include semiautomatic manufacturing or fabrication, your best welding power source selection may be the Lincoln Idealarc® DC-600. Rugged construction, simple controls and plenty of amperage for heavy duty applications on thick steel or other materials make this welder a sound investment. Add the outstanding traditional SCR rectifier arc action delivering high quality, attractive welds and your operators will agree – it's hard to go wrong with an Idealarc® DC-600.

Processes

Stick TIG MIG Flux-Cored Submerged Arc Gouging

Advantage Lincoln

•115V, 15 amps, duplex auxiliary power receptacle (60Hz models) makes it easy to power lights, grinders and other shop tools at your work station.

•Full range output voltage control for easy operation and precise control.

•Standard analog ammeter and voltmeter.

•Mode switch for selecting desired output characteristics.

•Windings and rectifiers protected against moisture and corrosive environments.

•Flat-top case with a small footprint can be placed under a workbench or stacked up to 3 high on top of each other.

•Manufactured under a quality system certified to ISO 9001 requirements and ISO 14001 environmental standards.

•Three-year warranty on parts and labor.

•Seven-year warranty on the power rectifier.

Description

Output | CC | DC | Input 3 | 60 |

CV | PHASE |

Sham pistols. Recommended General Options

Multi-Process Switch, Undercarriage, Paralleling Kit

Recommended Stick Options

Accessory Kit, Remote Output Control, Remote Control Cable Adapter

Idealarc 100

Recommended TIG Options

Pro-Torch™ TIG Torches, TIG Module, Control Cable, Control Cable Extension, Docking Kit, Hand Amptrol, Foot Amptrol, Amptrol Adapter Kit, Water Valve Kit, Deluxe Adjustable Gas Regulator and Hose Kit

Recommended Wire Feeder Options

LF-72, LF-74, LN-742, LN-8, LN-9, LN-9 GMA, LN-10, DH-10, LN-15, LN-23P, LN-25, LN-35, Cobramatic®, NA-3, NA-5, LT-7

Order

K1288-17 | Idealarc DC-600 | 230/460/3/60 |

K1288-18 | Idealarc DC-600 | 230/460/3/60 |

w/multi-process switch | ||

K1288-22 | Idealarc DC-600 | 230/460/575/3/60 |

TECHNICAL SPECIFICATIONS

Rated Output | Input | Dimensions | Net | ||||

Product | Product | Input | Current/Voltage/ | Current @ | Output | H x W x D | Weight |

Name | Number | Power | Duty Cycle | Rated Output | Range | in. (mm) | lbs (kg) |

K1288-17 | 230/460/3/60 | 108/54A | CV: | ||||

Idealarc® DC-600 | K1288-18 | 600A/44V/100% | 70-850A, 13-44V | 30.7 x 22.2 x 38.0 | 522 | ||

K1288-22 | 230/460/575/3/60 | 680A/44V/60% | 108/54/43.2A | CC: | (781 x 565 x 965) | (237) | |

90-850A, 24-42V |

Publication E5.40 5/05

www.lincolnelectric.com

FEATURES

PERFORMANCE

•The Idealarc® DC-600 is a multiprocess DC arc welding power source that produces outstanding arc characteristics on both constant voltage and constant current processes. This provides great welding versatility in a single power source.

•The Idealarc DC-600 is designed for GMAW (MIG), FCAW, and submerged arc welding processes within the capacity of the machine, plus the capability of stick, and air carbon arc gouging up to 3/8' (10mm) diameter. It produces outstanding performance with a single range continuous control potentiometer.

FEATURES

•3-position field or factory installed Multi-Process Switch option allows quick change from electrode positive or negative semiautomatic/automatic wire feed welding to stick, TIG or air carbon arc gouging.

• Air carbon arc gouge with up to 3/8' (10mm) diameter carbons.

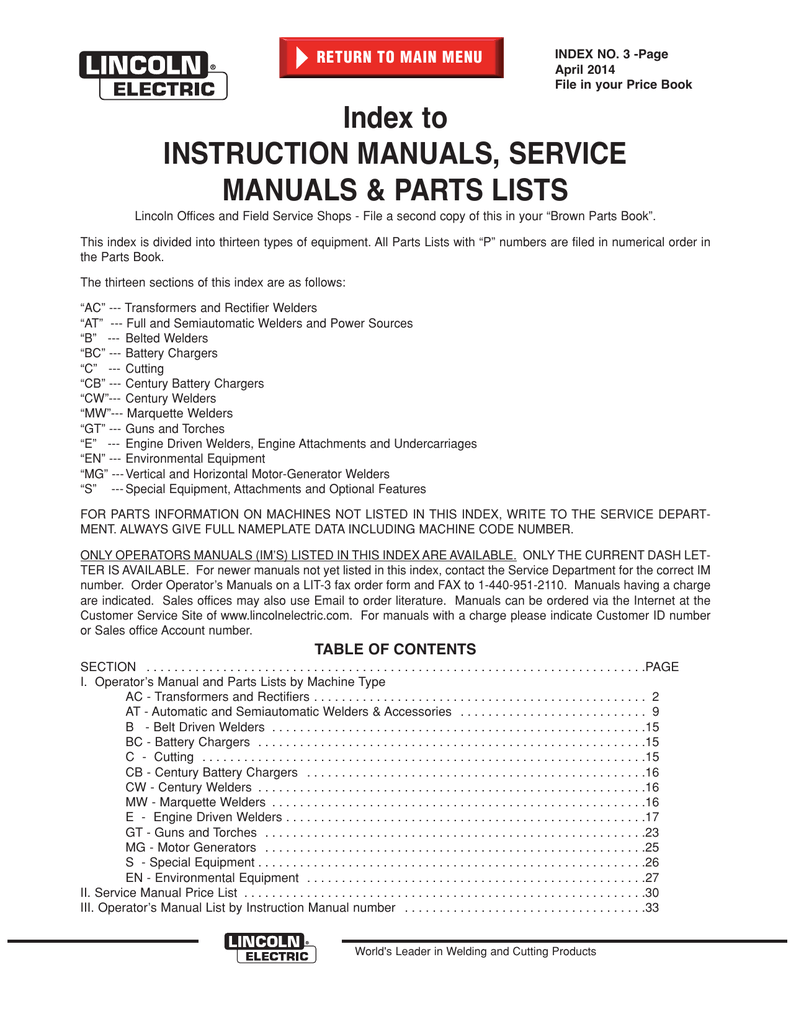

1. | 2. | 3. | 4. | 5. | 6. | 7. |

Key Controls

1.Ammeter/Voltmeter

2.Local/Remote Output Control

Idealarc Dc-1000 Service Manual

3.Output Control Potentiometer

4. Mode Selection Switch

5.Weld Terminals On or Remotely Controlled

6.On/Off Switch

7.Power Source Pilot Light

8. Strain Relief for Terminal Strip Connection | 8. |

9.14-Pin MS-Style Connector for Wire Feeder Connection

10.115 VAC, 15A Covered Outlet

Lincoln Idealarc Dc 1000 Manual

10. | 9. |

Idealarc Dc 1000 Service Manual Instructions

QUALITY AND RELIABILITY

•Fan-cooled with electronic and thermostatic protection from current overload and excessive temperatures.

•Manufactured under a quality system certified to ISO 9001 requirements and ISO 14001 environmental standards.

•Three-year warranty on parts and labor.

•Seven-year warranty on the power rectifier.